Welcome to Zhongjda Industry

Toggle Navigation

When you're deciding on a finish for your aluminum extrusions, it's natural to consider various options. Painting, anodizing, and powder coating all have their own unique advantages. So, which one should you choose? And why might you consider one over the other? Today, we're talking about powder coating aluminum extrusions. Let's discuss how it works, the benefits it offers, and the main reasons to consider powder coating your aluminum extrusions.

How the Powder Coating Process Works

Powder coating is the process of spraying electrostatically charged paint (in powder form) onto your extrusions. Unlike liquid paint, powder coating doesn't require a solvent. So it's VERY important that the surface of every extrusion is properly pre-treated.

1) Pre-treat the Aluminum Surface

The pre-treatment process involves removing dust, grease, and any other foreign particles. That way, the technician can ensure good adhesion and the powder coat won't flake.

2) Apply Powder to the Extrusions

The technician sprays the powder through an electrostatic spray gun. The positive charge makes the powder bond with an electrically-grounded extrusion.

3) Heat Aluminum Profiles in the Curing Oven

The technician puts the extrusions into a large curing oven. The oven bakes the extrusions until you have a uniformly-melted coating.

4) Cool the Extrusions

After the extrusions are baked, the technician removes them so they can cool off. Once cool, you'll have a smooth, hardened coating.

The Main Benefits of Powder Coating Aluminum Extrusions

✔ It gives you a wide range of beautiful, bright color options.

✔ It's more environmentally friendly than liquid paint.

✔ The coating is thick and it bonds to the aluminum, so it doesn't chip or peel easily.

What Makes Powder Coating Environmentally Friendly?

One of the main reasons powder coating can be preferable over paint is that there are no solvents or VOCs (Volatile Organic Compounds). That means there's no damage to the environment while it's being sprayed.

Unlike wet paint, the waste from powder coating isn't hazardous. The process doesn't produce much waste because over-sprayed powder can be collected and reused.

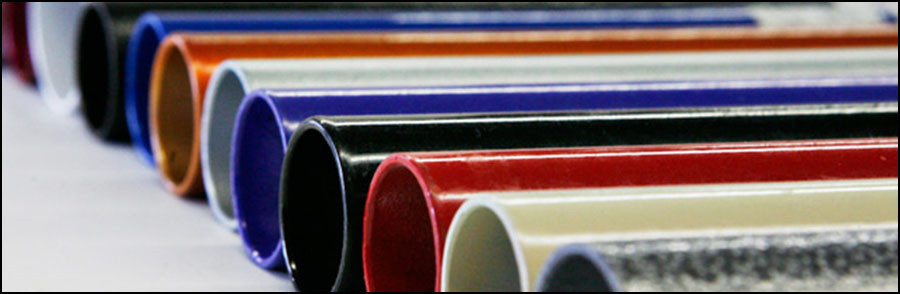

What Kind of Color Options are Available?

Especially when compared to anodizing, powder coating will give you a very broad range of colors. You won't get the same“aluminum”look that you achieve with anodizing. But, you can get an array of bright, beautiful hues or unique textures. When followed up with sublimation, you can even get aluminum that looks like wood. The amount of choice you have, in terms of appearance, can be virtually limitless.

Should I Powder Coat Aluminum Extrusions?

Of course, the answer to this question will depend on the final application and the look you're going for. But if you want bright colors or unique textures, powder coating can be a good choice. It is also more environmentally friendly than liquid paint, so that is another factor to consider. If you need a colorful, environmentally-friendly finish, powder coating may be good for your project. Also, here are some more aluminum finish options for you to consider.